HUATEC Portable UCI Hardness Tester Ultrasonic Hardness Tester Rockwell Hardness Tester

Features:

●Disadvantages are obvious for the hardness measurement commonly used like Brinell, Rockwell, Vickers, Leeb, etc.

● Rockwell and Brinell with heavy loading force and big indentation, lead to serious destruction on sample surface.

● Vickers apply optical measurement, but only professional technicians can operate smoothly, impossible to measure hardness of heavy work piece, installed machinery and permanently assembled parts.

● Leeb hardness tester apply rebound and indirect method to measure hardness, easily lead to big deviation when convert to Brinell, Rockwell and Vickers scales.

● Ultrasonic hardness tester HUH-5M applies ultrasonic contact impedance method to do comparative hardness measurement for testing pieces, with advantages of high accuracy, efficiency, portable and easy operation.

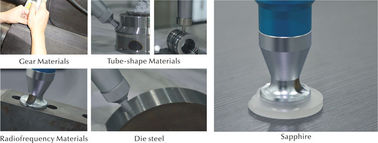

● Ultrasonic hardness tester HUH-5M is widely used to measure hardness of small forgings, cast material, weld inspection, heat affected zone, Ion-nitride stamping dies and molds, forms, presses, thin walled parts, bearings, tooth flanks, etc.

Manual Probes Features:

● Introduced latest ultrasonic sensor technology

● Obtain accurate hardness value without auxiliary devices

● Support 360° quick measuring

● Excellent human engineering design easy to hold

● Suitable dimension and weight of probe is convenient to control

● Quick and accurate measuring for edge and fixed position of specimen

● Micro indentation, Non- Destructive for specimen

Specifications:

| Product Name |

UCI Ultrasonic Hardness Tester |

| Model |

HUH-5M |

| Loading Force |

10N/20N/50N/98N |

| Indenter |

136°Vickers Diamond Indenter |

| Measuring Range |

HB: 85-650;HV 80-1599; HRC 20-70;HRB: 41-100; HRA: 61-85.6

HS: 34.2-97.3;Mpa: 255-2180N/mm

|

| Measuring Accuracy |

HV:±3%HV; HRC:±1.5HRC; HB:±3%HB; HLD:±5HLD; |

| Measuring Direction |

Support 360° |

| Data Storage |

To save 1000-groups of measuring data and 20-groups of calibration data |

| Hardness Scale |

HV,HB,HRC, HLD |

| Data Display |

Loading force, Testing-times, Testing result, Average,

Maximum,Minimum,Deviation and Conversion scale. |

| Hardness Indication |

LCD display |

| Operating Environment |

Temperature:-10℃~50℃; Humidity: 30%~80%R.H |

| Operating Voltage |

DC 6V |

| Instrument Dimensions |

160x80x31mm |

| Net Weight |

Approximate 500g(Without probe) |

Standard Delivery:

| Standard Delivery |

quantity |

Standard Delivery |

quantity |

Standard Delivery |

quantity |

Standard Delivery |

quantity |

| HUH-5M main unit |

1 |

Probe Cable |

1 |

Anti Vibration Case |

1 |

English Operation Manual |

1 |

| 50N/98N Manual probe |

1 |

Com Cable |

1 |

Screw |

1 |

Warranty Card |

1 |

| Standard Rockwell Block |

1 |

USB Cable |

1 |

Qualification Certificate |

1 |

Packing List |

1 |

Manual Probe Specifications:

| Probe Type |

UCI-1K |

UCI-2K |

UCI-5K |

UCI-10K |

| Testing force |

10N |

20N |

50N |

98N |

| Diamter |

22mm |

22mm |

22mm |

22mm |

| Length |

154mm |

154mm |

154mm |

154mm |

| Oscillating Rod Diameter |

2.4mm |

2.4mm |

3mm |

3mm |

| Roughness of measuring surface |

Ra<3.2um |

Ra<5um |

Ra<10um |

Ra<15um |

| Min weight of test material |

0.3kg |

0.3kg |

0.3kg |

0.3kg |

| Minimum thickness |

2mm |

2mm |

2mm |

2mm |

Block Specification:

| Hardness Range |

Uniformity |

Roughness |

Dimension |

| (28~35)HRC |

±1.5HRC |

Ra=0.02um |

Ø90x16mm |

| (38~43)HRC |

±1.5HRC |

Ra=0.02um |

Ø90x16mm |

| (48~53)HRC |

±1.5HRC |

Ra=0.02um |

Ø90x16mm |

| (58~63)HRC |

±1.5HRC |

Ra=0.02um |

Ø90x16mm |

| (300~500)HV1 |

±3%HV |

Ra=0.02um |

Ø90x16mm |

| (300~500)HV5 |

±3%HV |

Ra=0.02um |

Ø90x16mm |

Support Ring Specifications:

| Support Ring Name |

Plan Support Ring |

Small Cylinder Support Ring |

Big Cylinder Support Ring |

| Application |

Plan Test Piece |

Diameter 8-22mm Test Piece |

Diameter 16-80mm Test Piece |

Guidelines for selection and use of UCI instruments:

| Load |

Model |

Features |

Typical Applications |

| 98N |

Standard length (manual) |

Relatively large indentation; requires minimal surface

preparation

|

Small forgings, cast material, weld inspection, HAZ |

| 50N |

Standard length (manual)

Extended length (manual)

Short probe (manual)

|

For general use

30 mm extended length

Reduced length (90 mm); electronics in separate housing

|

Induction hardened or carburized machine parts, for

example, camshafts, turbine weld inspection, HAZ

Measurement in grooves, on gear tooth flanks and roots

Turbine blades, inside wall of pipes with Ø >90 mm

|

| 10N |

Standard length (manual)

Extended length (manual)

Short probe (manual)

|

Load is easy to apply and provides control to test on sharp radii

30 mm extended length

Reduced length (90 mm); electronics in separate housing

|

Ion-nitride stamping dies and molds, forms, presses,

thin walled parts

Bearings, tooth flanks

Turbine blades, inside wall of pipes with Ø >90 mm

|

| 8 N |

Motor probe style |

Load is applied by servomotor |

Finished precision parts, gears, bearing raceways |

| 3 N |

Motor probe style |

Load is applied by servomotor; rather small indentations |

Thin layers, for example, copper or chromium on steel

cylinders;

Copper rotogravure cylinders;

Coatings, case hardened parts

|

| 1 N |

Motor probe style |

Load is applied by servomotor; rather small indentations |

Thin layers and coatings |

Testing Stand HU-100:

| Testing Stand |

HU-100 |

| Material |

Stainless Steel |

| Weight |

8.8Kg |

| Dimension(LxWxH) |

200 x 200 x 332mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!