Product Description:

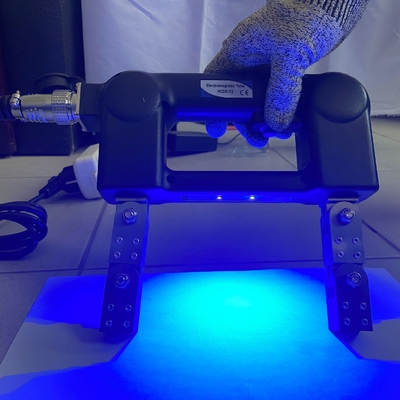

Magnetic Particle Testing Equipment is the perfect choice for flaw detection. It has a highly effective leg magnetic yoke which enables the user to detect any flaws in the material under test. It also provides a split shell for convenient maintenance, which allows the user to replace the power switch, cable socket, and lamp easily. The shell of the testing equipment is designed to have a good heat resistance that does not deform even at high temperatures. It also has an air flow inside with low temperature rise, providing excellent heat dissipation. The power source of the equipment can be either AC or DC. In addition, it is also equipped with white light and ultraviolet light, with a touch controlled switch and adjustable brightness.

It is an ideal choice for leg magnetic yoke and magnetic particle flaw detector due to the ease of maintenance and its reliable durability. Thanks to its ergonomic design, the Magnetic Particle Testing Equipment provides excellent performance. It is an affordable choice for flaw detection that is suitable for a wide range of materials.

Features:

- Product Name: Magnetic Particle Testing Equipment

- White and UV light: White Light And Ultraviolet Light, Touch Controlled Switch, Adjustable Brightness

- Color: The Shell Color Can Be Customized

- Voltage: 240V,230V,220V,110V,36V Various Voltages

- Basic function: AC Magnetization, Directly Plugged In For Use

- Heat resistance: The Shell Has Good Heat Resistance And Does Not Deform At High Temperature

- Portable Magnetic Flaw Detector, Magnetic Yoke Flaw Detector, Portable Magnetic Flaw Detector.

Technical Parameters:

| Maintenance |

The split shell is used for convenient maintenance, user can replace power switch, cable socket, lamp friendly |

| Voltage |

240V, 230V, 220V, 110V, 36V various voltages |

| Basic function |

AC magnetization, directly plugged in for use |

| Duty cycle |

50%, max on time is 90 seconds |

| Product name |

Yoke Flaw Detector, Portable Magnetic Flaw Detector, Yoke Detector |

| White and UV light |

White light and ultraviolet light, touch controlled switch, adjustable brightness |

| Power |

AC/DC |

| Appearance |

Controllable injection molding, no defects in appearance |

| Heat resistance |

The shell has good heat resistance and does not deform at high temperature |

| Color |

The shell color can be customized |

Applications:

Huatec HCDX Series Magnetic Particle Testing Equipment

- Brand Name: Huatec

- Model Number: HCDX series

- Place of Origin: China

- Basic function: AC Magnetization, Directly Plugged In For Use

- Power: AC/DC

- Appearance: Controllable Injection Molding, No Defects In Appearance

- Duty cycle: 50%, Max On Time Is 90 Seconds

- White and UV light: White Light And Ultraviolet Light, Touch Controlled Switch, Adjustable Brightness

The Huatec HCDX series magnetic particle testing equipment is ideal for checking the surface of metal parts for flaws or cracks. The HCDX series uses AC magnetization technology to detect even the smallest flaws and defects. It also features a controllable injection molding process and no defects in appearance. The duty cycle of the HCDX series is 50%, with a maximum on time of 90 seconds. It also comes with white light and ultraviolet light, touch controlled switch, and adjustable brightness.

As a dependable magnetic flaw detector, the HCDX series magnetic particle testing equipment is suitable for many applications such as in the automotive, aerospace, and manufacturing industries. It is reliable, accurate, and durable, and can detect even the smallest flaws and defects. Its AC/DC power supply makes it convenient and easy to use.

The HCDX series magnetic particle testing equipment is the perfect choice for those looking for a reliable and accurate magnetic flaw detector. Its AC magnetization technology, adjustable brightness, and controllable injection molding make it the ideal choice for a variety of applications. With its durable construction and reliable performance, the HCDX series is the perfect choice for anyone looking for a dependable magnetic flaw detector.

Customization:

Huatec offers a range of custom Magnetic Particle Testing Equipment with the brand name HCDX series. This product is made in China and is equipped with white and UV light, touch controlled switch, adjustable brightness, and a split shell for convenient maintenance. The user can replace power switch, cable socket, and lamp parts for easy maintenance. The appearance of this product is controllable injection molding, and it has no defects in its appearance. The basic function is AC magnetization and it is directly plugged in for use. This yoke flaw detector is available in various voltages such as 240V, 230V, 220V, 110V, and 36V. It is equipped with a leg magnetic yoke for reliable magnetic flaw detection.

Packing and Shipping:

Packaging and Shipping for Magnetic Particle Testing Equipment:

Our Magnetic Particle Testing Equipment is packaged securely for safe shipping. All components are wrapped in protective material to prevent damage in transit. We use standard shipping boxes and containers for all product shipments.

We offer various shipping options to meet our customers' needs. We ship worldwide via air freight, sea freight, or ground transportation. All orders are shipped with a tracking number to ensure you know exactly when your product is delivered.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!