HMT-MA6 MMMT Metal Magnetic Memory Stress Detector

1. Principle and Application Scope of Magnetic Memory Testing

1.1 Principle of Magnetic Memory TestingMetal Magnetic Memory Testing (MMMT) is a new non-destructive testing and diagnostic method for detecting stress concentration and fatigue damage in workpieces. The principle of MMMT is based on the spontaneous magnetization phenomenon that occurs in ferromagnetic workpieces in areas of stress and deformation during their loading and operational processes.

1.2 Application Scope of the HMT-MA6 Metal Magnetic Memory Stress DetectorThe HMT-MA6 metal magnetic memory stress detector has a wide range of applications, mainly including aerospace, aviation, railways, electric power, boiler pressure vessels, petrochemical industries, as well as various welded joints and other ferromagnetic metal components. It provides early diagnosis of equipment fatigue damage caused by stress concentration due to material discontinuities (i.e., defects) in in-service equipment. Specific applications include: service life assessment of load-bearing structural components; rapid maintenance of large equipment; condition evaluation of pipelines, elbows, and boiler pressure vessels; condition evaluation of turbine rotors; condition evaluation of generator retaining rings; condition evaluation of gears and bolts; and various weld status assessments, among others

.2. Technical Parameters of the HMT-MA6 Metal Magnetic Memory Stress Detector

|

2.1 Main Unit Configuration Specifications

|

2.1.1 Equipped with a Core I7 processor, with expandability for storage, basic configuration includes 8GB RAM and 256GB storage.

2.1.2 Software developed based on the WIN10 operating system, compatible with standard office computers.

2.1.3 10.1-inch capacitive touch display.

2.1.4 DC 10.8V 9AH large-capacity lithium polymer battery.

|

|

2.2 Technical Specifications

|

2.2.1 Magnetic field (Hp) range: ±4000 A/m (ampere per meter)

2.2.2 Magnetic field measurement resolution: 0.01 A/m

2.2.3 Main unit magnetic field (Hp) measurement channels: 16 channels

2.2.4 Acquisition method: displacement-free equal time sampling or coded step sampling

2.2.5 Scanning speed: 0.01–0.5 m/s

2.2.6 Relative error in length measurement: less than ±2%

2.2.7 Data transmission between main unit and probe via a 2-meter data cable, with network communication capabilities, compatible with portable magnetic flux leakage probes

2.2.8 Main unit operating system with Simplified Chinese interface, equipped with Simplified Chinese user manual and instructions.

2.2.9 Integrated touch display and touch operation for convenient observation during testing.

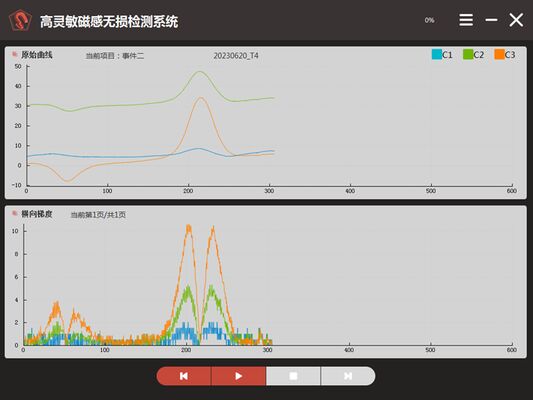

2.2.10 Instrument software includes functions such as original curve, gradient curve, time base chart, polar coordinates, 3D view, and data analysis.

2.2.11 Main unit operating system and software are upgradeable to meet future user requirements and have data analysis capabilities that meet standard update requirements.

|

|

2.3 Other Main Unit Specifications

|

2.3.1 Main unit weighs 4.5 kg, portable for a single person, and the overall packaging meets airport and customs shipping requirements.

2.3.2 Main unit is waterproof and dustproof, suitable for harsh on-site conditions.Operating temperature of the host: -20℃ to 50℃, storage temperature: -30℃ to 70℃ Celsius.

2.3.3 The host is battery-powered, ensuring that the entire system can operate continuously for 6 hours.

|

|

2.4 Probe Technical Specifications

|

2.4.1 Pen-type 90-degree bent probe T90, 1 detection channel, can detect adjacent workpieces with a spacing of no more than 35mm.

2.4.2 Pen-type straight handle probe T0, 1 detection channel, can detect adjacent workpieces with a spacing of no more than 40mm.

2.4.3 Single-wheel probe T1, 3 detection channels, single-wheel rolling, detection width 30mm.

2.4.4 Double-wheel probe T2, 3 detection channels, double-wheel rolling, detection width 30mm.

2.4.5 Pin shaft detection probe T3, 3 detection channels, front and rear wheel rolling, can detect pin shafts with diameters of 18mm-60mm.

2.4.6 Four-wheel probe T4, 3 detection channels, four-wheel rolling, detection width 30mm.2.3.7 Variable surface detection probe T5, 5 detection channels, four-wheel rolling, can detect cylinders with diameters of 30mm-60mm.2.3.8 Variable surface detection probe T6, 5 detection channels, four-wheel rolling, can detect cylinders with diameters of 80mm-120mm.

|

3 Instrument Configuration List

3.1.1 Portable touch-screen host, 1 unit

3.1.2 Pen-type 90-degree bent probe, 1 unit

3.1.3 Pen-type straight handle probe, 1 unit

3.1.4 Single-wheel probe, 1 unit

3.1.5 Double-wheel probe, 1 unit

3.1.6 Four-wheel probe, 1 unit

3.1.7 Pin shaft detection probe, 1 unit

3.1.8 30-60mm variable surface detection probe, 1 unit

3.1.9 80-120mm variable surface detection probe, 1 unit

3.1.10 Battery charger (220V AC input), 1 unit

3.1.11 2 batteries

3.1.12 Instrument carrying case, 1 unit

3.1.13 English product manual, 1 copy, electronic version, 1 copy

3.1.14 Data analysis USB drive, 1 unit

3.1.15 Certificate of Conformity, Warranty Card, Configuration List, 1 copy each

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!