Auto Calibration Function Portable Ultrasonic Flaw Detector SD Card Touch Screen

Features

●High-precision quantification and positioning to meet the requirements of near and far distance detection

●The near-field blind zone is small, can meet the detecting requirements for small-diameter and thin-walled pipe.

●Auto calibration function:one-button auto calibration,easy to operate, automatic test probe “P Delay”,”K value”,”X value” and the velocity

●Automatic display the defect echo position(Depth:d, Horizontal:p,Distance:s, Amplitude,dB,ф )

●Switch three scales freely(Depth:d, Horizontal:p,Distance:s)

●Auto gain, peak envelope, peak memory functions, which can improve the detection efficiency.

●Automatically record the flaw detection process and dynamic playback

●φ value calculation:Forging flaw detection by straight probe, can find the highest wave to conversion φ value automatically

●500 independent channels(can be expandable), which can input and store the detection standards of any industries freely, do not need to carry the standard blocks for on-site inspection.

●Store, playback 500 A-scan waves and data freely

● The DAC, AVG, and TCG curves (depth compensation) are automatically generated and can be segmented. The sampling points are unrestricted and can be corrected and compensated.

●14 built-in inspection standards

●Free to enter any industry standards

●Pulse width and strength can adjustable

●B scan and B color scan function;

●Can communicate with the computer, and export WORD. File, also the detection report

●IP65 ABS plastic case, sturdy and durable,water-proof and dust-proof, and excellent anti-interference ability

●Use (wireless) communication software to analyze data print reports, etc;

●260,000-color true color screen, is suitable for working environment under strong light or low light

●High performance lithium battery, can work continuously for 8-10 hours

●Real-time clock recording: real-time flaw detection date, time tracking record, and storage

●Power-down protection, storage data can not lost

●Flaw detection parameters can be automatically tested or preset

●Digital reject, does not affect gain and linearity

●Gain compensation: Db attenuation can be corrected for surface roughness, curved surfaces, long-range flaw detection of thick work-pieces, etc.

●Can operate the flaw detector by software at the PC, achieving the goal of computer-controlled flaw detector to detecting

Technical Specification

| Display |

7 inch TFT color screen,800*480 resolution |

| Operation mode |

Button, Rotary, Touch Screen |

| Power supply |

Lithium Ion Battery |

| Battery capacity |

5.0Ah |

| Power voltage |

12V |

| Power quantity |

1 |

| Working time |

≥8 hours |

| Adapter input |

DC100~240V 50Hz/60Hz |

| Adapter output |

AC 12V |

| Adapter power |

36W |

| Data storage |

SD card(16G) |

| Alarm |

1 |

| Working Temperature |

-10℃~45℃ |

| Storage Temperature |

-20℃~60℃ |

| IP Grade |

IP65 |

| Dimension |

245*155*55mm |

| Weight |

1.18kg(included battery) |

| Conventional UT Model |

| Probe Connector type |

LEMO 00 |

| Channel Type |

Single channel |

| Channel Num |

500 group(able to be scaled) |

| Pulse Type |

Negative sharp wave |

| Transmit Voltage |

50~350V,step in 50V |

| Damping |

560Ω |

| Gain |

0~110dB,step:0.5/2/6/12dB |

| Gain Fine Adjustment |

-4~+4 |

| Surface compensation |

All Gain Range |

| Working Frequency |

0.5~20MHz; |

| Probe Type |

Single,Dual, Through, Immersion type |

| Filter |

Three optional:

1~4MHz/0.5~10MHz/2~20MHz

|

| Detection Mode |

Negative/Positive/Two-way/RF |

| Reject |

0~80%,step 1% |

| Testing Range |

0~15000mm,Minimum display range:15mm(in steel) |

| Material Velocity |

100~20000m/s |

| Pulse displacement |

-10~1000mm |

| P DELAY |

0~200us |

| X-VAL |

0~100mm |

| Guide |

Weld, Sheet, Forging inspection |

| Testing Point |

Peak/X-val/J val |

| Measurement |

Gate:Amplitude,Amplitude dB value,Range,Horizontal distance,Vertical distance,The difference value between A and B Gate

Cursor:2 cross cursors, can test the horizontal and vertical distance, and the distance between cursors(under B scan function)

|

| Gate |

Gate start:all range |

| Gate width:all range |

| Gate level:10~90%,step:1% |

| Curve |

DAC, maximum six curves, meet to NB/T 47013,GB/T 11345,GB/T 29712, and other standards |

| TCG, maximum six curves |

| AVG |

| Other functions |

Full screen, cursor switch(range/Height/Horizon), single/continuous auto gain(10~100%, step 10%), echo compare,echo full, peak envelope,peak memory,fast scan,outside mode,screenshot |

| Peak freeze/Crack depth/Gate expansion//curved surface modification/ B scan/Flat weld simulation//video |

| Alarm |

Sound and light alarm |

| Sensitivity Leavings |

≥65dB(200mm—Φ2FH,2.5PΦ20) |

| Horizontal linearity error |

≤0.3% |

| Vertical linearity error |

≤3% |

| Amplitude linearity error |

≤±2% |

| Attenuator accuracy |

20dB ±1 dB |

| Dynamic range |

≥32dB |

| Distant resolution |

≥26dB |

| Noise Level |

<40×10-9 V/ |

Standard Configuration

| |

Name |

QTY |

|

| |

| 1 |

Main unit |

1 |

|

| 2 |

Power adaptor |

1 |

|

| 3 |

probe connecting cable |

2 |

|

| 4 |

Instrument case |

1 |

|

| 5 |

Instruction manual |

1 |

|

| 6 |

Straight probe 10mm 2.5MHz |

1 |

|

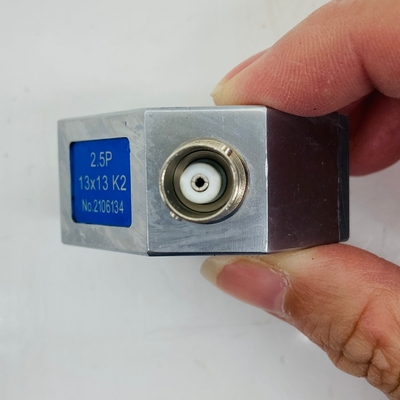

| 7 |

Angle probe 13x13 K2 2.5MHz |

1 |

|

| 8 |

Warranty card |

1 |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!