Internal and External Broken Wire Tester Elevator Steel Wire Rope Fracture Elevator Wire Rope Testing

1. LF testing sensitivity of local injury detection

The detector detects the minimum metal cross-sectional area change and the minimum size of damage length corresponding to local damage.

2. LMA testing sensitivity of metal cross-sectional area loss detection

The detector detects the minimum metal cross-sectional area change and the minimum size of damage length corresponding to the loss of metal cross-sectional area.

3. LMA repeatability error of metal cross-sectional area loss

Within the range of the instrument and under the same detection environment and conditions, the maximum value of the random error obtained by repeated continuous measurement of the variation of the same metal section area in the same sample.

4. LMA linearity error of metal cross-section area loss

Within the range of the instrument, the absolute value of the maximum deviation between the measured curve of the metal cross-sectional area of the sample tested by the instrument and the measured value of the measured cross-sectional area of the group of metals.

5. LMA error of indication of metal cross-sectional area loss

Within the range of the instrument, the loss of the metal cross-sectional area measured by the instrument is subtracted from the actual loss of the metal cross-sectional area.

6. Linear error of Wire Rope LMA linearity error of metal cross-section loss

Within the range of the instrument, the absolute value of the maximum deviation between the metal cross-sectional area loss measured by the detector and the calibration curve fitted by a group of metal cross-sectional area loss measured by the instrument under the condition of the same metal cross-sectional area loss length.

7. Resolution of testing distance

The detector can detect the minimum distance of resolution.

8. Dual-function instrument

The detector can detect and show changes in the metal cross-sectional area loss (LMA) on one channel and local damage (LF) on the other. The signal recording device of this detector can be a computer, graph recorder or other matching equipment.

9. Single-function instrument

The detector cannot simultaneously detect and display the change of metal cross-sectional area loss and local damage, but can only detect and display one of them. The recording signal device of this detector can be computer, graph recorder or other matching equipment.

10. Wire rope electromagnetic tester

The principle and composition of the detector meet the requirements of GB/T 21837-2008 standard, and have the functions of detection distance display, data storage or recording.

Wire rope flaw detector is a collection of advanced flaw detection technology at home and abroad. Using digital processing and network technology, a portable intelligent wire rope electromagnetic nondestructive testing instrument is developed. It is widely used in mining, cableway, lifting equipment, elevator, port machinery, cable bridge and other fields.

Wire rope flaw detector can be real-time display of the internal and external broken wires, corrosion, wear, metallic cross-sectional area changes of quantitative values, according to the current standards and regulations make the diagnosis report and solutions, has realized the rapid diagnosis of wire rope damage, reduce double wire rope detection time, detection does not affect the normal production, solve the labor, low efficiency of inspection line, unable to test the internal damage and artificial factors and so on. The instrument is easy to carry, simple to operate, and can be operated by operators after simple training, with high detection accuracy, good repeatability and accurate damage location.

Technical indicators

Full range of wire rope diameter range can be detected: Φ 1.5-300 - mm (need to configure different series specifications sensor)

Relative speed between sensor and wire rope: 0.0 -- 6.0 m/s best: 0.3 -- 1.5 m/s

The best gap between sensor guide sleeve and wire rope is 2 -- 6 mm, and the allowable gap is 0 -- 15mm

Broken wire defect (LF) detection capability

Qualitative: single concentrated broken wire qualitative detection accuracy is 99.99%

Quantification: the number of broken roots in a single place allows one or one equivalent root to misjudge

More than 100 times of quantitative detection with single centralized root breakage without error, the accuracy rate is ≥92%

Quantitative rate of change of metal cross section (LMA)

Permissible error of detection sensitivity repeatability: ±0.055%

Permissible error of detection accuracy indication: ± 0.2%

Position (L) detection capability: detection length percentage error: ±0.2%

Power supply: computer battery power 5V

Sensor weight: commonly used specification < 10kg

Ambient temperature: -10℃~40℃ atmospheric pressure: 86~106Kpa relative humidity: ≤85%

Product Overview

◆ can on-line test the wire rope internal and external broken wire, wear, corrosion, deformation, loose strands, jump wire, material changes and other defects.

◆ the test results can meet the standards of different industries and can be displayed in the form of the number of broken wires and the ratio of the broken wire area to the total broken wire area.

◆ computer USB interface for direct sampling, processing and analysis, with online sound and light alarm and real-time display results.

◆ sensor circular structure, circumferential surround, axial magnetization, magnetization of the wire rope to saturation state.

◆ The sensor adopts alloy aluminum shell, which is waterproof, dustproof, shockproof and moisture-proof.

◆ stable work, reliable performance, high detection accuracy, strong anti-interference performance, accurate data.

◆ software to adapt to Windows98/2000 / xp/Vista/windows7 various computer operating systems

◆ in accordance with the provisions of the national metrology law and the national production safety law, each instrument shall be inspected by the national metrology institute as a third party in accordance with the American standard ASTM1571, and the test report shall be issued to obtain the legal qualification.

◆ widely used in mining, ropeway, lifting equipment, elevator, port machinery, cable bridge and other fields.

Technical core and legal qualification

1. Virtual instrument: infinite uncertainty of wire rope.Only by using virtual instrument technology, replacing traditional instrument with software, and using computer to directly sample, we can ensure no missed inspection and wrong judgment, just like watching a movie, scanning the whole process of wire rope, the results are accurate and repeatable.

2. Three-determination instrument: according to the national standards for scrap of wire rope in different industries, this product applies electromagnetic qualitative, quantitative, positioning, online nondestructive testing of wire rope internal and external broken wire, rust, wear, metal sectional area change, loose strands, jumping wire, deformation, material abnormalities and other defects.

3. Legal instruments: according to the provisions of the national metrology law and the national production safety law, each instrument is inspected by the national metrology institute according to the American standard of astm1571-2006 and GB/ t21387-2008 as a third party, and the test report is issued to obtain the legal qualification.

System configuration and model

1. Elevator wire rope diameter is 8-16mm

2. The total model of wire rope computer flaw detector is E15/E20

| |

The serial number |

Content |

Qty. |

Comment |

|

The sensing

unit

|

1. |

E15 Excitation polymagnetic sampling sensor(Automatic distance positioning to form an encoder) |

1 |

8-16mm All kinds of elevator wire rope can be tested (single rope) |

| 2. |

E20 Excitation polymagnetic sampling sensor

(Automatic distance positioning to form an encoder)

|

1 |

8-16mm All kinds of elevator wire rope can be tested (multi-rope) |

|

conversion

unit

|

3. |

RADFDigital converter

(Online monitoring and real-time alarm)

|

1 |

The module is imported from USA |

| 4. |

8344 Signal switching |

1 |

|

| 5. |

USB Serial converter line |

1 |

|

|

To deal with

unit

|

6. |

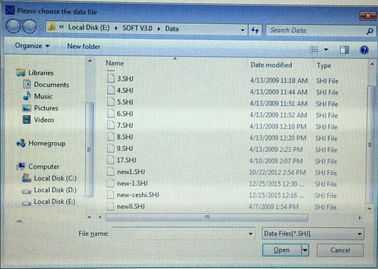

V3.0 Version Processing package |

1 |

|

| 7. |

Laptop |

1 |

Including computer bag plus mouse |

| The attachment |

8. |

Standard packing case |

1 |

|

| 9. |

Safety line |

1 |

|

| 10. |

Issued by the national legal metrological institution

Third-party test report

|

1 |

The use of the instrument obtains legal qualification |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!