HCDX-2000 Movable type Magnetic Particle Flaw Detector

*HCDX-2000 movable type magnetic particle flaw detector can conduct AC or DC magnetization for parts. It also has automatic demagnetization function, without additional demagnetization device.

| Magnetizing current: (AC) |

0 ~ 2000A (effective value), continuously adjustable, with power off phase control

(HWDC) 0-2000A (average)

|

| Demagnetization |

(AC/HWDC) 2000 ~ 0A |

| Coil (optional) |

inner diameter φ 250mm, outer diameter φ 380mm |

| Temporary load rate |

30% |

| Demagnetization time |

<5s |

| Input voltage |

220V (single-phase)/380V (three-phase) |

| Frequency |

50Hz/60Hz |

*The instrument has its own roller, which is flexible and light. It is applicable to aviation, machinery, automobile, railway, ship, pressure vessel and other manufacturing industries. It can detect the whole, part and abnormal parts of the parts, and also make the large-sized workpieces magnetized locally in sections.

*The instrument adopts 8-bit single chip microcomputer as the control core, and realizes continuous regulation of magnetization and demagnetization current through accurate acquisition of AC zero crossing signal and current regulating switch signal. It supports the function of limiting the maximum value of magnetizing current to prevent the current from mistakenly adjusting and ablating the workpiece. It has power off phase control function, and the remanence is stable. It is suitable for continuous method and remanence method flaw detection.

*During automatic demagnetization, the instrument automatically attenuates from the current magnetizing current value to zero; The instrument uses silicon controlled rectifier to adjust its conduction angle to control the magnetizing and demagnetizing current, so as to realize contactless adjustment of large current and prolong the service life of the instrument.

*The instrument is equipped with supporting rod copper rod, which can be used for flaw detection by supporting rod method; The output cables can also be connected with each other and wound on the shaft workpiece for winding method flaw detection. In addition, additional magnetizing coils or simple supports can be configured according to user requirements to form a simple bed flaw detector for small workpiece detection.

Main functions:

Flaw detection method: strut method (direct electrification method), winding method, coil method

Magnetization method: AC magnetization, DC magnetization (HWDC/FWDC)

Demagnetization method: AC demagnetization adopts remote demagnetization (attenuation method), and DC demagnetization adopts ultra-low frequency demagnetization

Technical parameters:

Magnetizing current: (AC): 0 ~ 2000A (effective value), continuously adjustable, with power off phase control

(HWDC) 0-2000A (average)

Demagnetization: (AC/HWDC) 2000 ~ 0A

Coil (optional): inner diameter φ 250mm, outer diameter φ 380mm

Temporary load rate: 30%

Demagnetization time:<5s

Input voltage: 220V (single-phase)/380V (three-phase)

Frequency: 50Hz/60Hz

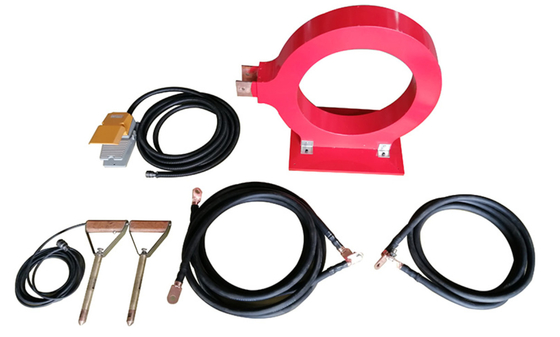

Standard configuration:

Movable magnetic particle flaw detector host 1

Pole probe 1 set

Output cable 1 set

Standard test piece 1 set

Foot switch 1 set

Manual, certificate, packing list and warranty card 1 set

Optional configuration:

Magnetizing coil

Wound cable

Simple water tank for recovery and utilization of magnetic suspension

Magnetic suspension spray recovery system

Ultraviolet light

Fluorescent magnetic particle

Shading room

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!