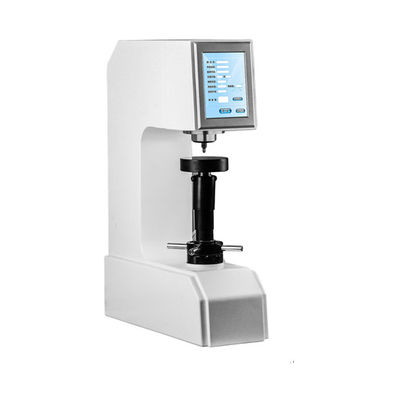

HR-150/45DX Rockwell, Superficial Rockwell Hardness Tester

Product Features:

1. Italian design, modern and beautiful appearance, stable structure

2. Touch screen interface, easy operation, multi-language versions

3. Available for using after staring up, unnecessary for installing weights and debugging

4. Electric loading, closed-loop control

5. All Rockwell scales, 30 in total

6. Automatically apply the initial load and main load

7. Automatic correction of high, medium and low hardness numbers

8. Automatic correction of load, with the force accuracy increased by a numerical level

9. Set the password protection and parameters

10. More information of sample and testing

11. Data stored in USB flash disk, EXCEL format, easy for compiling and processing

12. Adopt the modular design, easy maintenance

13. Larger sample space, huge sample stage

Technical Parameters:

| Product model |

HR-150/45DX

|

| Exchanging scales |

Rockwell, Superficial Rockwell |

| Dwell time |

0-60s

|

| Initial load of Rockwell |

10kgf (98N) |

| Total load of Rockwell |

60kgf (588.4N) 100kgf (980.7N) 150kgf (1471N) |

| Initial load of Superficial Rockwell |

3kgf (29.4N) |

| Total load of Superficial Rockwell |

15kgf (147.1N) 30kgf (294.2N) 45kgf (441.3N) |

| Load value error |

Less than 0.5% |

| Hardness testing range |

HRA: 20-96 HRB: 20-100 HRC: 20-70 HRD: 40-77 H R E: 70-100 HRF: 60-100 HRG: 30-94

HRH: 80-100HRK: 40-100HRL: 50-115HRM: 50-115 HRR: 50-115

|

| Testing rage of Superficial Rockwell |

HR15N: 70-94; HR30N: 42-86; HR45N: 20-77;

HR15T: 67-93; HR30T: 29-82; HR45T: 10-72

|

| Hardness measurement accuracy |

0.1 |

| Executive standard |

GB/T230.1 GB/T230.2 national standard JJG112 verification regulation

|

| Max Height of Sample |

220mm |

| Distance of Indenterto outer wall |

200mm |

| Hardness reading |

LCD display |

| Data output |

USB flash disk |

| Power supply |

AC220V

|

| Net weight |

About 70kg |

Application Fields:

Industrial production, Inspection of product quality on processing technology. Ferrous and nonferrous metals, Hardened steel, tempered steel, annealed steel, hardened steel, sheet of various thicknesses, carbide materials, powder metallurgy materials, hardness and thermal spray coating.

Sheet metal, thin-walled pipe, hardened steel, and small parts of hardness.

Widely used in machinery manufacturing, metallurgy plants, universities, laboratories, etc.

Standard Accessories:

| Name |

Quantity |

Name |

Quantity |

| Diamond Rockwell indenter |

1 |

Ball indenter with the diameter of 1.5875 mm |

1 |

| Hardness block(HRB, HRC high, HRC low, HR15N, HR30N, HR30T) |

6 |

Large, medium, V-type testing bench |

1 for each |

| USB flash disk |

1 |

Dustproof plastic housing |

1 |

| Power line |

1 |

Operating Instruction, Product Qualification Certificate |

1 for each |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!