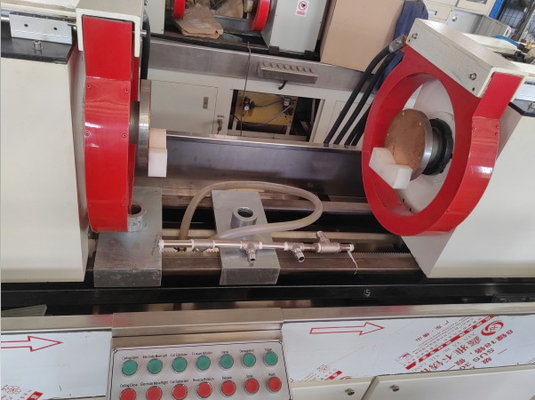

HMP-5000 Fluorescent Magnetic Particle Flaw Detector

Work principle

Utilizing interaction between magnetic leakage field and magnetic powder at the defect of the workpiece. It takes advantage of the difference between the permeability of surface & near-surface defects of steel products (such as cracks, slag inclusion, hair lines, etc.) and magnetic permeability of steel, the magnetic field at the discontinuity of these materials will be distorted after magnetization, forming part of the magnetic flux leakage and generating a magnetic leakage field, using the characteristics of the magnetic leakage at the defect site to absorb magnetic powder, thereby attracting magnetic powder to form magnetic powder accumulation at the defect - magnetic marks, under appropriate lighting conditions, the defect location and shape are revealed accordingly.

| Technical Parameters |

|

|

Current

Name

|

HWDC/FWDC

( Optional)

|

|

| |

| Circumferential magnetization current (A) |

5000 |

|

| Longitudinal magnetization MMF (AT) |

12000,16000,18000,20000 |

|

| Optional coil inner diameter (mm) |

350,400,500,600 |

|

| Optional maximum electrode spacing (mm) |

1000,1500,2000,3000,5000 |

|

| Main engine |

Integrated/split type (control cabinet separated from main engine) |

|

| Sensitivity |

Clearly display on Type A test piece (30/50,15/50,7/50 ) |

|

| Duty cycle |

≤30% |

|

| Control mode |

Manual/Automatic |

|

| Operation interface |

Digital ammeter/Touchscreen |

|

| Clamping mechanism |

Manual/Pneumatic |

|

| Rotation mode |

Manual/Electric |

|

| Tail electrode movement |

Manual/Electric |

|

| AC magnetization method |

Circumferential, longitudinal, composite magnetization |

|

| AC demagnetization |

Automatic decay demagnetization |

|

| Rectification mode |

Half-wave rectification (HWDC) / Full-wave rectification (FWDC) |

|

| AC/DC magnetization method |

AC circumferential magnetization,

DC circumferential magnetization, AC longitudinal magnetization, DC longitudinal magnetization, AC circumferential + DC longitudinal composite magnetization, DC circumferential + AC longitudinal composite magnetization

|

|

| DC demagnetization |

Ultra-low frequency demagnetization |

|

| UV lamp |

Suspended / Handheld |

|

| Spray time |

3–6 seconds / Manual control |

|

| Magnetization time |

0.5–2 seconds per cycle |

|

| Rotation observation time |

5–10 seconds |

|

| Demagnetization time |

3–5 seconds per cycle |

|

| Air supply |

0.4-0.8MPa |

|

| Power supply |

Three-phase five-wire, 380V±10%, 50Hz |

|

| Overall Dimension (mm) |

Length: 1.5m + electrode spacing |

|

| Width: 2,000; Height: 2,200 |

|

Application

It is designed to detect surface and near-surface micro-defects (e.g., cracks, slag inclusions) of ferromagnetic workpieces (such as bolts, pins, bushings, gears, gear rings, crankshafts, etc.) caused by forging, quenching, grinding, fatigue, and other processes.

Compliance Standards

Magnetic particle flaw detector: GB/T 8290—2011

Observation conditions for magnetic particle inspection: GB/T 5097-2020 / ISO 3059:2012

ASTM standard: Magnetic Particle detection method ASTM E1444-01

EU/International standards: DIN EN ISO 9934-2:2003

Technical Parameters

Detection range: Diameter: 0–260 mm, Length: 1,200 mm (customizable range 0–3,000 mm)

Detection method: Fluorescent or non-fluorescent magnetic particle detection

Magnetization method: Circumferential, longitudinal, and composite magnetization

Electrode spacing: Adjustable 0–1200 mm, customizable range 0–6000 mm

Clamping mechanism: Manual/pneumatic clamping

Magnetization current: 0–6000A

Demagnetization effect: Residual magnetism <0.3 mT

Sensitivity: Clearly display on A1-type standard test piece (15/50 μm)

Power supply: Three-phase five-wire AC 380V 50Hz

Standard Configuration:

Magnetic Particle Inspection Main Unit

Digital Ammeter

Lightproof Darkroom with Shielding Curtain

Suspended UV Lamp

Fluorescent Magnetic Particles

Magnetic Suspension Concentration Test Tube

Magnetometer

Optional Configuration:

Semi-enclosed dark room

Fully enclosed dark room

DC Magnetization (HWDC/FWDC)

Touch screen control panel

Rotation observation (manual/electric)

Electrically moved tail electrode

Flame-proof copper mesh mat

| Model |

Configuration |

Tail Electrode Movement |

Rotation Observation |

Operation Panel |

| Manual |

Electric |

Manual |

Electric |

Digital Ammeter |

Touchscreen |

| Economical |

Basic Darkroom |

√ |

|

√ |

|

√ |

|

| Standard |

Semi-enclosed Darkroom |

√ |

|

|

√ |

√ |

|

| Advanced |

Fully-enclosed Darkroom |

|

√ |

|

√ |

|

√ |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!