HXRF-120X IP54 Certification Handheld XRF X-ray Fluorescence Spectrometer

Application field and characteristics

1,Excellent performance (for field use, non-destructive, fast, accurate)

High precision, fast speed, close to the laboratory level of analysis, can directly display the alloy grade and element percentage content and ppm content. The entire analysis process can be completed in only a few seconds, and the alloy grade identification takes only 1 to 2 seconds.

2,One-click operation, even non-technical personnel can easily master.

3,Nondestructive testing(NDT)

It does not damage or affect the performance of the tested object, does not harm the internal organization of the tested object, and has no damage during the whole test process.

4,Analysis software

Remote control system, windows based PC/Android based mobile phone can operate the instrument through the software, to achieve data synchronization across multiple platforms (instrument, PC, mobile and cloud), the software has data analysis, spectrum display, report printing and other functions, the instrument client has the function of sending analysis reports by email; Remote control system, windows based PC/Android based mobile phone can operate the instrument through the software to achieve data synchronization across multiple platforms (instrument, PC, mobile and cloud), the software has data analysis, spectrum display, report printing and other functions, the instrument client has the function of sending analysis reports by email.

5,Waste recycling and sorting

Recycling and reuse of scrap metal, complex and diverse alloy types and materials, on-site analysis, detection and sorting. For both buyers and sellers in the transaction to make rapid and reliable judgment. Quantitative analysis of ferrous alloy (stainless steel, etc.), copper alloy, aluminum alloy, copper-iron alloy, lead-tin alloy, hybrid alloy and other metal components, as well as rapid material identification and sorting on site.

6,Application areas and safety, standards (power plant, machinery, petrochemical, military, etc.)

Alloy material Identification (PMI) incoming inspection; Inventory material management; Installation material reinspection, prevent in petrochemical construction, metal smelting, pressure vessels, power plants, petrochemical, fine chemical, pharmaceutical, casting, aerospace and other industries, mixing or use of unqualified materials will produce serious safety accidents, to ensure the material safety of process equipment. Adapt to American Society for Materials and Testing (ASTM), Chinese National standard (GB), UNS, power industry standard (DL), API, JIS, GMP, TSG, machinery industry standard (JB) and other industry and international and domestic standards.

7,Quality control and quality Assurance (QC/QA) and effective error prevention (PKKA-YOKE)

In the metal processing and manufacturing industry, the quality control and quality assurance (QC/QA) of materials (raw materials), semi-finished products, and finished products (PKKA-YOKE) are essential, and mixing or using unqualified materials will bring losses to enterprises. From small metal processing plants to large aircraft manufacturers.

8,Data Processing and Enterprise Resource Planning (ERP)

WIFI, wireless Bluetooth and other ways of data transmission, files can be sent by E-mail, Bluetooth synchronous transmission, software synchronous transmission.

Technical parameters and specifications

| HXRF-120X Handheld X-ray fluorescence spectrometer |

| detector |

High-performance Sipin detection components |

| Excitation source |

45KV/200uA- Silver target/Tungsten target end window integrated micro X-ray tube and high voltage source |

| Element detection range |

1, the atomic number is 20 to 92 elements between calcium (Mg) and uranium (U)

2, equipped with a large area detector to analyze the main elements in the alloy: Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Ag, Cd, Sn, Sb, Ta, W, Pb, Bi and Mg,Al,Si,P,S a total of 25 (can continue to add)

|

| Detection object |

solidity |

| Analytical method |

Direct Reading Analysis + Basic Parameter Method (FP)

IP54 certification (splash and dust proof)

|

| Software |

Remote control system, windows based PC/Android based mobile phone can operate the instrument through the software, to achieve data synchronization across multiple platforms (instrument, PC, mobile and cloud), the software has data analysis, spectrum display, report printing and other functions, the instrument client has the function of sending analysis reports by email; |

| Weight |

≤1.75kg(include battery) |

| Microcomputer display system |

1, semi-transparent semi-anti-industrial custom touch screen ≥5 inches

2, resolution 1080*720

3. SDD detector

4, support WIFI

5, password security protection

|

| Power source |

1, rechargeable lithium battery, standard 6800mAh, voltage: 7.2V; Sustainable work up to 12 hours;

2, the instrument has the function of hot swap, delay power off, replace the battery is no need to shut down, the battery has its own power display;

|

| Charging mode |

1, universal adapter charging current power supply; |

| Collimator, filter |

1, special anti-radiation material collimator, inner diameter 3MM

2, no filter, save switching time, software to deduct background interference

|

| Front-end test window |

≤9mm*5mm "Waist" type window |

| Test report sending mode |

E-mail Transmission, Bluetooth synchronous transmission, software synchronous transmission |

| Data transmission mode |

Wifi,Bluetooth |

| Maintenance mode |

Remote software upgrade and diagnosis, on-site maintenance, diagnosis |

| User management |

Multi-level user management function (can create multiple accounts, so that the person number corresponds, convenient management and data traceability) |

| Protective cover |

Instrument is equipped with protective cover, with instrument calibration, anti-radiation, anti-damage functions (non-standard) |

| Material sensing and instrument status alerts |

1, the body has a material sensing function, can intelligently identify whether there is a test object in front.

2, intelligent status display light, through the intelligent status display light shows three working states (red flashing indicates that the detection is under way, green flashing indicates that there is no object to be measured in front, green long bright indicates that there is something to be measured in front)

|

| Operating environment temperature and humidity |

humidness≤90%

-20℃ - +60℃

|

| security |

1, the instrument side measurement value ≤0.2μSv/h (after deducting background)

Note: The supplier shall provide in the response document a copy of the Handheld X-ray Analyzer (Leakage Ray) Report issued by the state-authorized legal metrology institution or the national testing center.

2, multiple safety protection, no test without radiation;

3, the radiation level at work is far lower than the international safety standard, and has no sample air test, automatic close X-ray tube function.

|

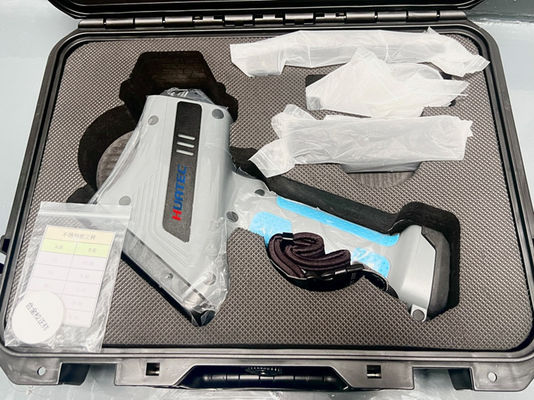

| attachments |

Standard:

1, three defense military protection box, with waterproof, dustproof, shock absorption effect.

2, test software instrument end, PC end, mobile phone end 1 set each

3, rechargeable lithium battery battery *2

4, universal battery charging adapter *1

Optional accessories: pedestal test bracket, protective cover

|

Analyzable family of alloys

●Iron base alloy series (stainless steel, chromium/molybdenum alloy steel, low alloy steel, tool steel, seamless steel)

●Nickel base alloy series (Nickel alloy, nickel/cobalt superalloy)

●Cobalt base alloy series

●Titanium base alloy series

●Copper base alloy series (bronze, brass, copper-nickel alloy, etc.)

●Superalloy (molybdenum tungsten alloy)

●Aluminium base alloy

●Other alloys

The Hand-held Alloy Analyzer (XRF) is suitable for high temperature and high pressure industries such as boilers, containers, pipelines, and manufacturing

Material reliability identification (PMI) is an important means during production. In iron and steel smelting, non-ferrous metals, aviation

Metal materials are used in the production process of military and civilian key engineering industries such as aerospace, weapon manufacturing, submarines and ships

Material identification. In petrochemical refining, fine chemical industry, pharmaceutical, power station, aerospace and other engineering installation

Identify metal materials in the process to ensure equipment acceptance, material acceptance, and meet the specified requirements of the project.

It is a powerful tool for metal identification in scrap metal recycling industry.

Widely used in quality control, material classification, alloy identification, safety prevention, accident investigation and other on-site applications

In the scenario, alloy grade identification, metal composition rapid analysis, to solve the most basic raw material analysis of industrialization

The problem, the handheld alloy analyzer integrates the most cutting-edge scientific innovation, is the production process on metal materials

Powerful tool for line recognition. At the same time, users can create their own personalized analysis system according to their own needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!